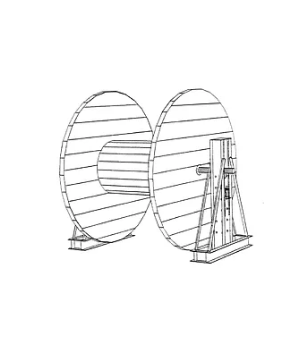

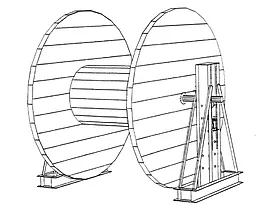

Portabe Cable Winding Machine For Hire

- This is a portable machine which can be used to wind cable on to drums on site.

- To reclaim scrap cable from demolition sites and modifications.

- Takes drums from 700mm to 1600mm in diameter and up to 1500kg in weight.

This is a machine for rolling cable back onto drums so that it can be reclaimed for use on jobs like demolition or refurbishment.

This machine was not designed to pull the cable out of its installed position, rather to roll the drum while the cable is fed onto it.

The machine will take drum sizes between 700mm and 1600mm in diameter, and 1000mm wide. Drums will be loaded onto and off the machine by pushing them over the lower of the two rollers and will sit and and be driven by the two rollers while being wound.

When positioning the machine, space should be left behind the machine to allow for drums to be loaded and unloaded. The operator will be facing the drum on the side with the higher roller. This is the side that the cable will be fed from.

Load your drum by sitting it on the two rollers. Drums must be dry and not missing any barrel boards. The flanges should be in good condition and the bolts should be tight.

Put the retaining shaft through the drum and fit the chains on either end. Take up the slack in the chains by hanging it in the chain hooks. The chains need not be tight, just take up the slack.

Plug the foot switch into the control box. Then the motor. Then a 10 amp 240 volt lead. The machine is now active and will run when the foot switch is pressed. Set the speed control on 5 and the forward/reverse switch to forward.

Rotate the drum and inspect it for splinters and loose nails that may damage the cable as it is

rolled.Attach the cable to the drum.The operator should stay at least 2 arm lengths from

the drum. There are pinch points where the drum touches the rollers, where the cable comes into contact with the

drum barrel, and between the cable and the drum flanges. Any body part coming into contact will result in sever

injury. Care should also be taken that the rollers and other parts of the machine don’t become fouled with debris

(string rope plastic etc).Now you can start the machine. Keep the speed low until you can lay the

cable on the drum in neat rows. This comes with practice. It is much more productive to keep the machine going

slowly than to stop and reverse to straighten up poor winding.This machine is not fitted with

measuring capability so it is a good idea to measure the cable before winding or to check if the cable is meter

marked. Keep a record of what you are putting on which drums as you go. You can wind numerous lengths onto one

drum but this makes it hard to get to the inside lengths.If the machine fails to start when the foot

switch is pressed then the electronics may have detected an electrical problem. Remove the power input and wait

for 2-3 minutes for the machine to go through a power down cycle. Then plug it in and try again.If

you still have any difficulty or you have any questions at all please contact us.

Get In Touch