ELECTRIC CRIMPER

23 TONNE HEAD

Crimping copper from 25mm to 630mm and crimping aluminum from 25mm to 500mm. Dies also available for aluminum sector cable.

60 TONNE HEAD

Crimping copper from 400mm to 800mm and crimping aluminum up to 800mm.

CUTTING HEADS

Small cutting head up to 60mm diameter and large cutting head up to 100mm diameter.

(12-tonne manual crimper also available)

BATTERY CRIMPER

Regarding efficient and reliable crimping in demanding environments, battery hydraulic crimpers are the best

choice for power utility and electrical professionals. These advanced tools are designed to handle various

crimping applications, ensuring the highest performance and reliability standards.

What is a Battery Hydraulic Crimper?

A battery hydraulic crimper is a specialised tool for crimping electrical cable lugs. These tools are essential

in applications ranging from small copper power cables to large underground power cables and overhead

distribution or transmission conductors. Battery hydraulic crimpers are valued for their versatility and

efficiency, making them a staple in numerous industries beyond power utilities.

Key Features of Battery Hydraulic Crimpers

Battery hydraulic crimpers have various features designed to enhance functionality and ease of use. Here are

some notable features to consider:

- High Crimping Capacity: Crimping up to 300mm² aluminium and 400mm² copper conductors

- Rotatable Crimp Head: A 355-degree head rotation allows flexibility in tight or awkward spaces.

- Pressure Biased Release Valve: Facilitates easy piston retraction, enhancing overall efficiency.

- Self-Contained Design: Offers ease of use without needing additional hydraulic equipment

Why Choose Battery Hydraulic Crimpers?

Battery hydraulic crimpers offer several advantages over traditional crimping methods. Their battery-powered

operation eliminates the need for external hydraulic pumps, making them more portable and convenient.

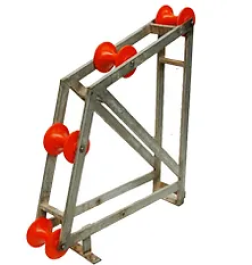

Pit Edge Rollers

Pitt Edge Rollers

Originally designed to take cable over the top edge of a pit, this is a 90 degree 500mm radius roller set.

It can be used to turn 90 degrees or less in lots of applications. It is especially good for bends on cable trays, both horizontal and vertical.

It can be attached to the tray or bolted to concrete or tray above leaving tray free for dressing in cable.

Corner Roller

Corner Roller

A 900 set similar to he pit edge roller with a 900mm radius.

Frame is in two pieces, joined in the middle by a pin.

Each side can be used separately for small angle changes in trench or on tray.

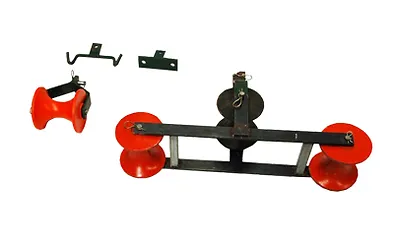

Cable Tray Feeding Rollers

Cable Tray Feeding Rollers

Specifically designed to feed cable onto and off cable tray. Used to lead cable onto or off cable ladder. Can also be used for slight changes in direction on ladder tray. It is designed to be attached to the tray, with it’s end roller hanging over the end of the tray. It can also hang over the side or over the outside flange of a turn.

No matter how the roller frame is fixed to the cable tray, the tray itself must be supported so that it can support the forces of the cable being pulled.

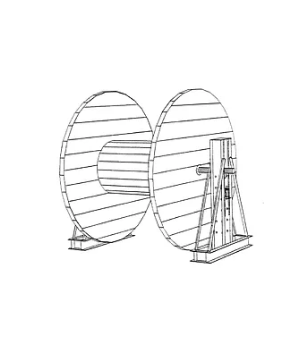

180 Degree Roller

180 Degree Roller

Designed for pulling cable out of vertically finishing conduits in slabs, where there is a concrete slab above, with the winch fixed to the floor. It has a removable bracket at the top, which can be bolted to the ceiling above.

These bolts and the concrete, must be strong enough to withstand more than twice the effort exerted by the winch, and it is likely that there will be more effort exerted on one side of the frame than the other.

In this application the winch rope, not the cable, is fed over the rollers. An open ended cable sock can be used to pull extra cable out of the conduit if needed.

This roller can also be used in a large concrete pit, opposite the end of conduits to turn the tow rope back on itself to come out of the pit, or for a 900 turn (in light duty applications), like at the end of a cable tray turning down a wall.

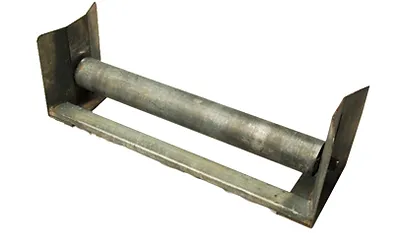

Conduit Feed Rollers

Conduit Feed Rollers

Inserted into conduit for a smooth cable path into conduit.

Sizes from 63mm to 150mm.

Can also be used in conjunction with a series of rollers dependant on application.

- Feeds cable into pipe.

- Allows for angle changes in pits.

- Conduit size from 80mm to150mm.

- Polyurethane roller.

Pit Roller

Pit Roller

This is an extension to the feeding roller. It ads a 900 turn to the exit of a conduit. It is fitted to the feeding roller via a longer shaft, which carries the roller casting, the feeding roller frame and the pit roller frame. The feeding roller is put into the conduit in the normal way and becomes the mounting for the whole assembly. It may need a bolt into the pit to hold it in place. We also have an adapted version of this roller set which has an added bracket. This allows the 900 turn to be bolted down to concrete such as where you have a conduit finishing vertical and flush with a floor. Where you need to head off to a winch.

... a note on pits

It is common to install a pit where an angle change is required in a conduit run (often referred to as a turning pit). This practice makes it easy to lay conduit but it complicates the pulling of cable. From a cable pulling perspective, it is far more productice to put a turn in the conduit, outside the pit and have the mouths of the conduit directly opposite each other in the pit. The turn should be after the pit, in the direction of the pull, so that lubricant can be applied to the cabl just before it goes around the bend.

The cost of extra conduit bends etc, is made up for by an easier cable pull with less equipment and complications.

Get In Touch